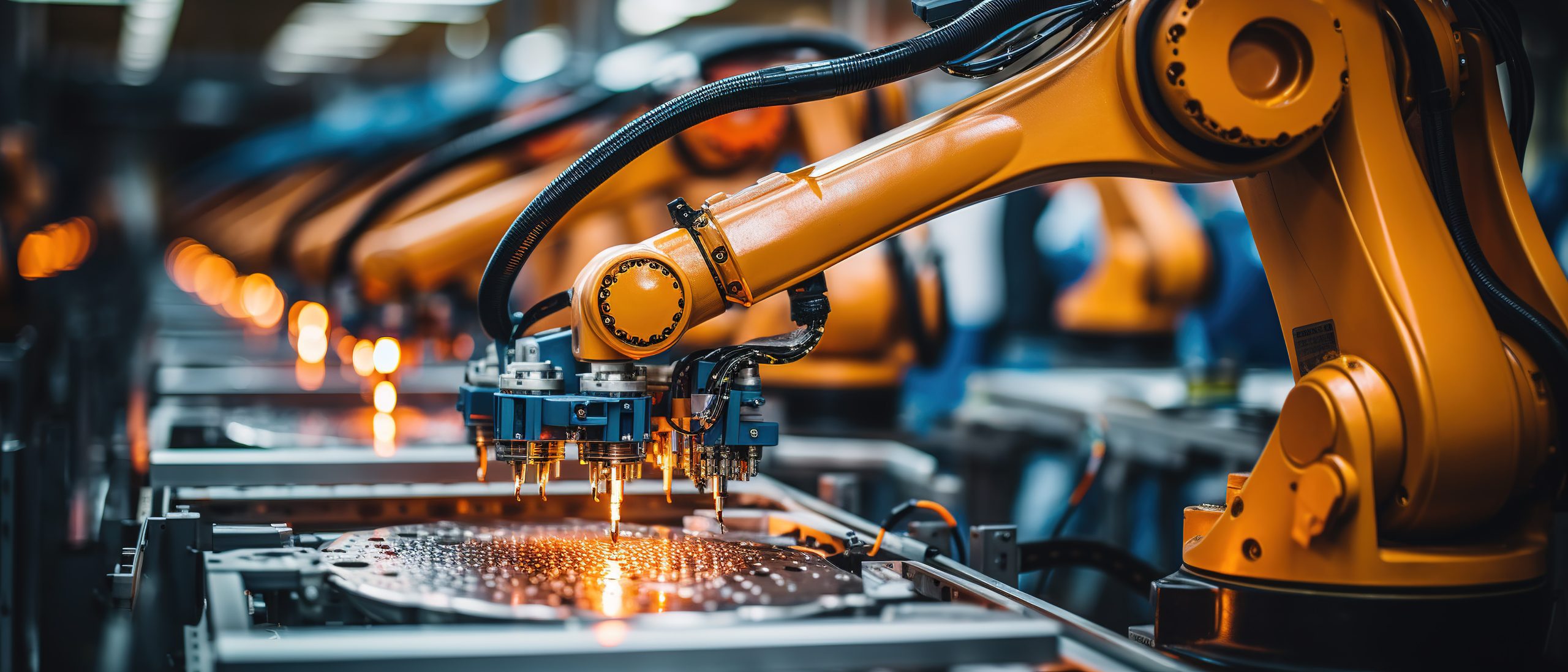

The industrial and manufacturing industries are one of the few industries that can incorporate many IoT applications, transitioning it from manual labour based into a more efficient and streamline sector. According to the International Data Corporation (IDC), the manufacturing industry is the biggest spender when it comes to purchasing IoT technologies, and it’s not hard to see why when it can facilitate production flow, manage inventories, increase plant safety and quality management, and create an efficient environment to operate in.

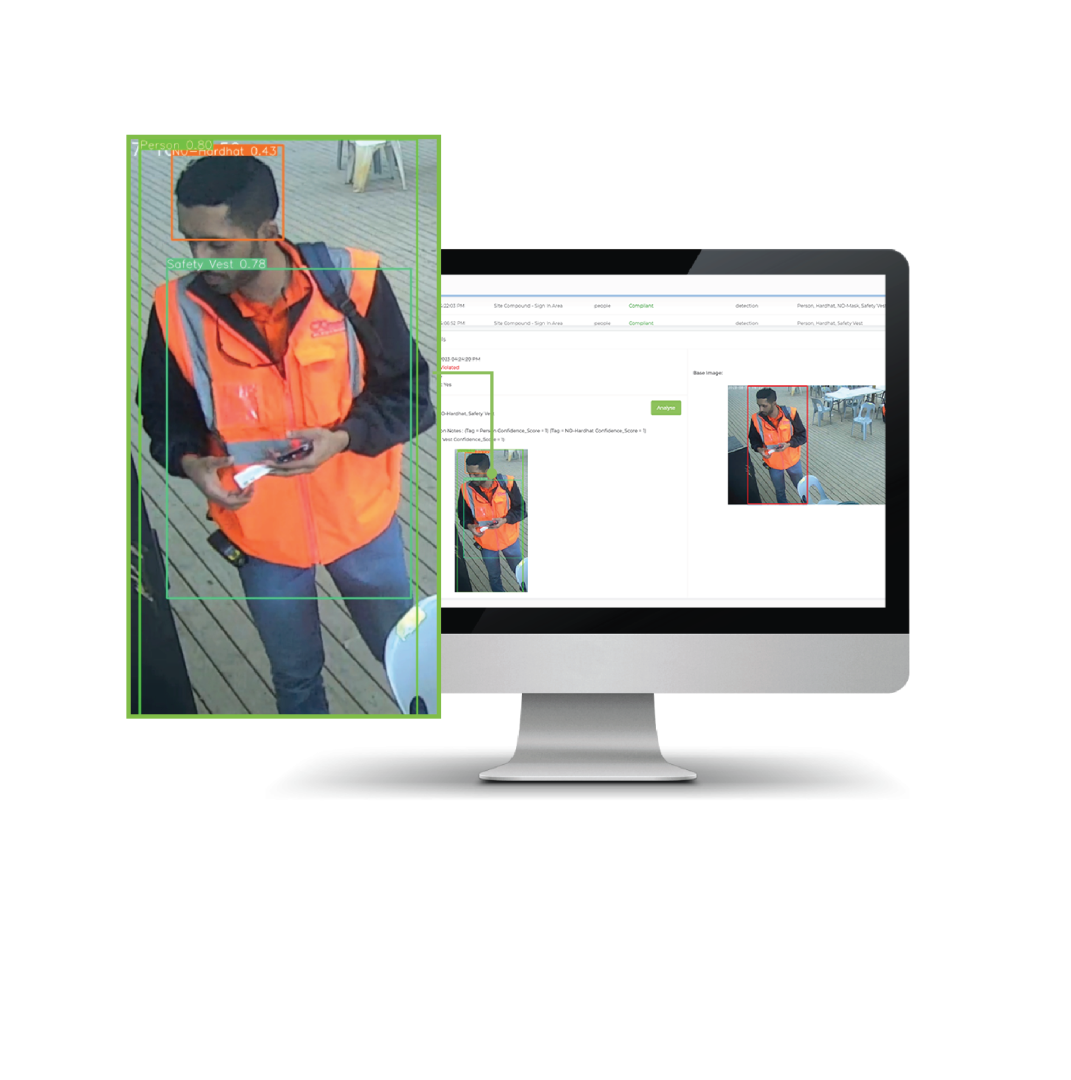

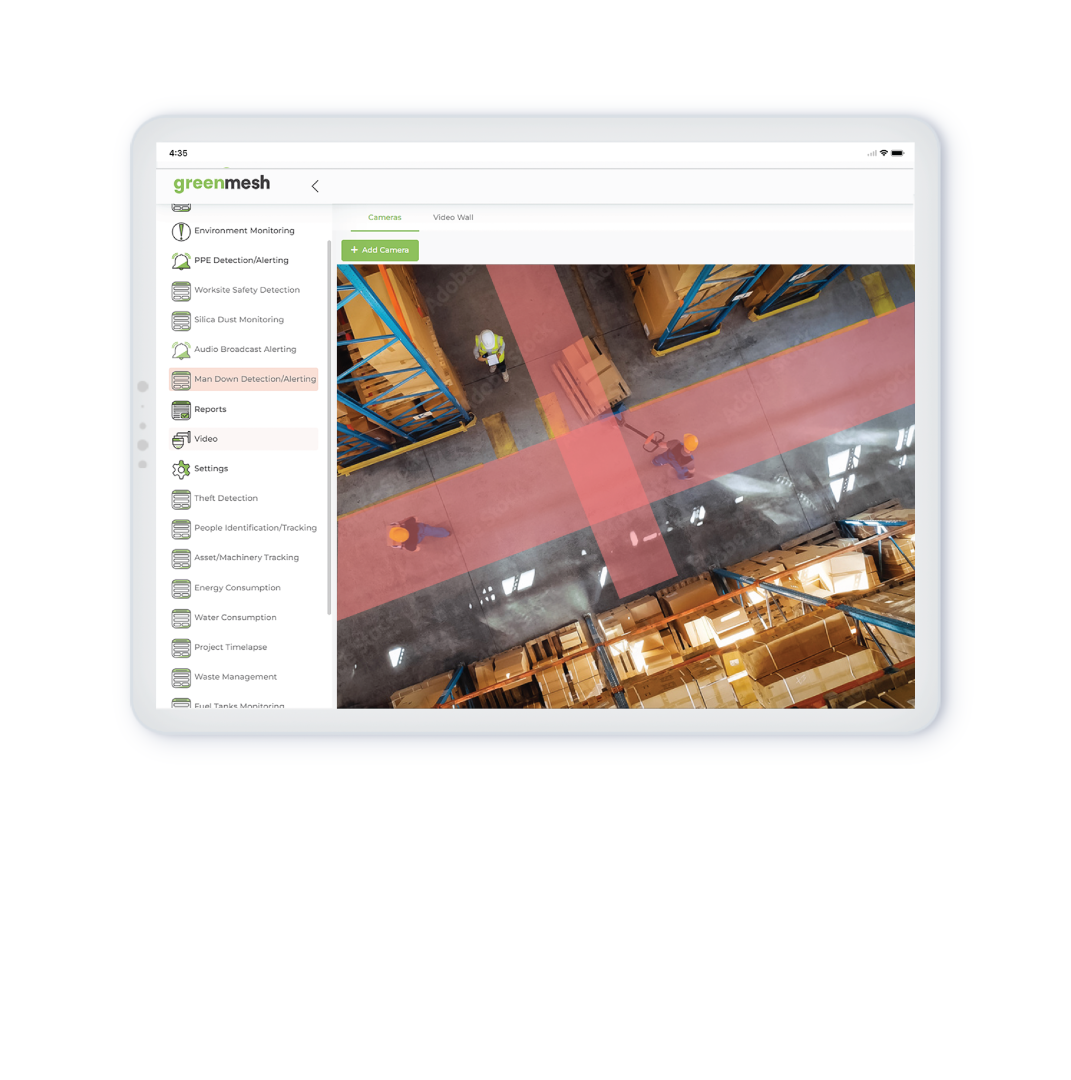

Through the use of sensors placed strategically throughout the warehouse/plant facility, you can monitor where peak areas of foot traffic is, and the peak periods within warehouses. This can improve safety, by identifying where the main slip and fall injuries on factory floor are (which areas and what times). With this information, you can better prioritise the health and safety of staff and visitors, and minimise risk for your organisation.