The mining, oil and gas industry is an economic powerhouse. According to McKinsey, within the next five years, this industry is set to generate an estimated US$930B. Through utilising and leveraging IoT solutions, which have a predicted economic impact of US$3.9T – US$11T economic impact over the same time span, this industry will strengthen its stance as a formidable economic player. By adopting IoT, this industry can not only optimise its processes and equipment but provide a safer and healthier work environment for its employees.

Reduce operational interruptions and enhance efficiency by avoiding unplanned shutdowns

Our sensors can monitor and create alerting features if emergency spills happen or if there are emergency shutdowns because of spillage. This will exponentially increase the speed at which these issues can be addressed and fixed/clean-up. This means non-productive downtime (NPD) is reduced, saving the company billions in dollars and reducing damage to the surrounding environment and ecosystems.

Sensors placed on drilling equipment means that alerting features can be set to notify you if there are any drilling issues. This will send the alert to the relevant staff if there are any potential drilling errors.

Minimise downtime and improve productivity preventing emergency shutdowns

767

total recordable mining. injuries reported in the NSW mining industry.

600000

workers exposed to silica dust,

30%

of workers had silicosis from the exposure.

Environment Monitoring

Ensuring a Sustainable Future:

Advanced Environmental Monitoring for Responsible Mining

People & Asset Tracking and Security

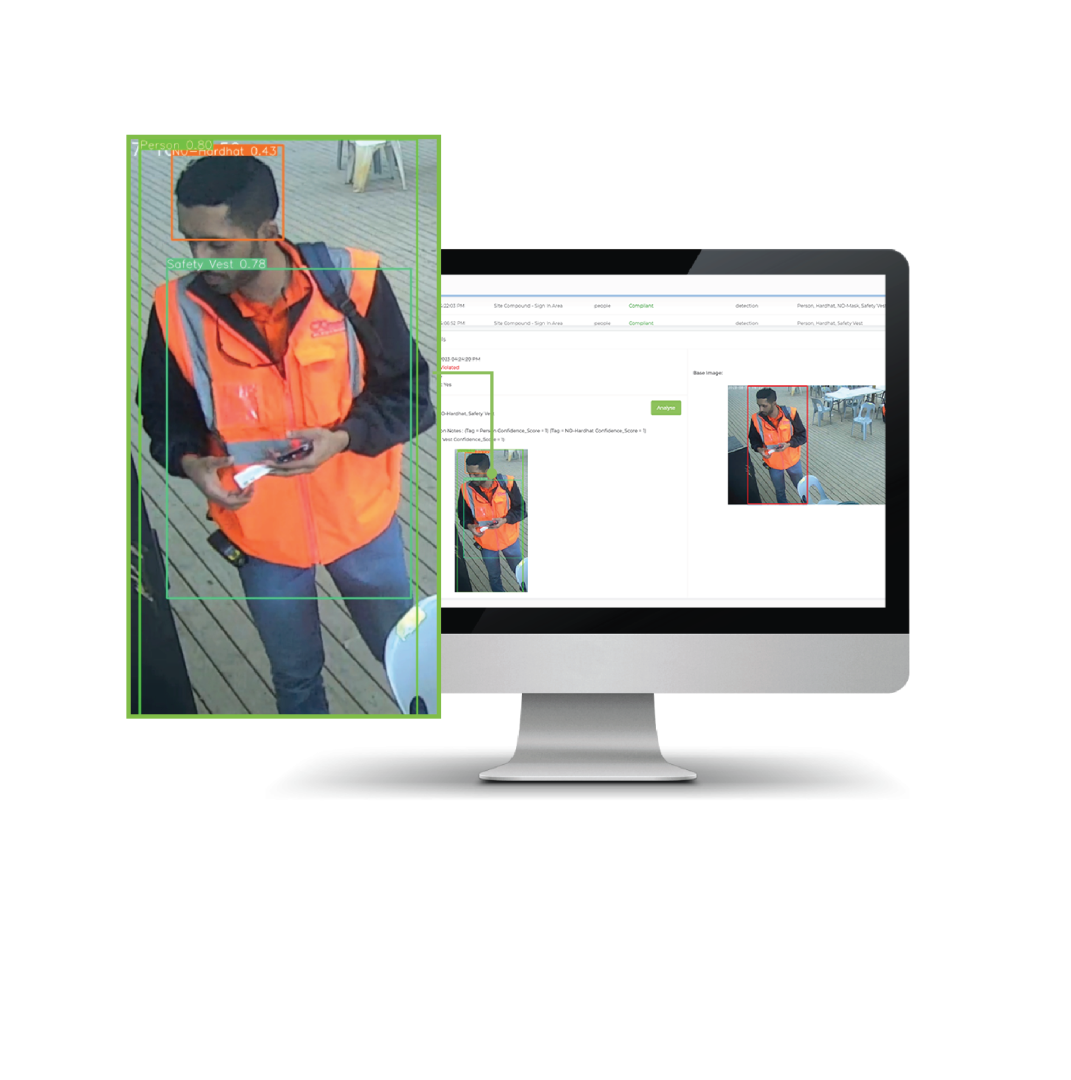

Object identification and differentiation

AI capabilities accurately identify and differentiate between people demographics, vehicle types, machinery assets, and provide real time location information.

Our sensors can monitor the number of people in an area in real-time. This will help determine the exact number of people if evacuation is needed due to an unexpected incident, resulting in reducing the number of fatalities. By using IoT-enabled safety measures, oil and gas companies can provide their workers with a safe working environment. The companies can also benefit from lower insurance and corporate liability.

Count and keep track of vehicles, machinery and assets entering underground and above ground.